Scientists develop an artificial muscle from carbon fiber capable of lifting 12,600x its own weight

07/17/2018 / By RJ Jhonson

What makes a muscle able to carry over 12,000 times its own weight? Carbon fiber and silicone, according to research published in the journal Smart Materials and Structures.

The artificial muscle, the creation of researchers from the University of Illinois, is made from siloxane rubber reinforced with carbon fiber. It is capable of supporting 12,600 times its own weight and 60 MPa (megapascal) of mechanical stress.

It can also provide tensile strokes higher than 25 percent and specific work of up to 758 J/kg (joule per kilogram), more than 18 times what natural muscles are capable of achieving.

The muscle has a coiled shape and can be electrically actuated. With the application of only 0.172 V/cm (volt per centimeter), a 0.4-millimeter muscle bundle can lift half a gallon of water by 1.4 inches.

“Coiled muscles were invented recently using nylon threads,” said Sameh Tawfick, mechanical science and engineering professor and one of the authors. “They can exert large actuation strokes, which make them incredibly useful for applications in human assistive devices: if only they could be made much stronger.”

To create a viable product, the team needed a material that was both lightweight and easy to obtain. Carbon fibers fit the bill. (Related: Researchers develop an artificial eye using a metalens and an artificial muscle.)

“To use carbon fibers, we had to understand the mechanism of contraction of coiled muscles. Once we uncovered the theory, we learned how to transform carbon fibers into ultra strong muscles,” Tawfick said.

Building the muscle doesn’t require a lot of steps. First, the carbon fibers are dipped into the guest material – uncured polydimethylsiloxane (PDMS) – a type of rubber silicone diluted with hexane the researchers chose for its “impressive performance.”

The fibers are then twisted using a simple drill until a yarn is created. Once the PDMS has cured, the yarn is twisted further until it has become fully coiled. It’s crucial for the coil to have a uniform radius.

The artificial muscle can also flex, said the researchers, thanks to the reaction of the PDMS to electricity, heat, and moisture.

“The muscles flex when the silicone rubber locally pushes the fibers apart within the tow, by applying a voltage, heat or swelling by a solvent. The internal pressure exerted from the silicone rubber onto the fibers makes the tow diameter expand and uncoil causing a contraction stroke along the length,” Tawfick explained.

The authors’ computations and the results of their experiment seem to agree that creating a better-performing artificial muscle was possible. They admitted that the tensile actuation of the muscle depended largely on the guest material’s ability to expand. PDMS can only handle so many repeated exposures to heat before it degrades, so the next guest material will have to fare better to create a stronger muscle.

Artificial muscles have an expansive set of potential applications

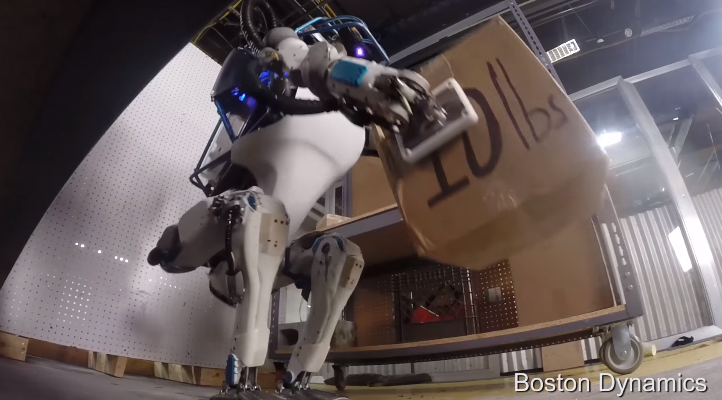

Artificial muscles serve as actuators in soft robotics where robots are made from pliable materials and are designed to imitate the movement, fluidity, and versatility of living organisms. They challenge the common perception of robots as rigid, clunky machines.

Artificial muscles make for low-cost actuators as they depend only on simple and readily available inputs like heat and air pressure to create motion. The one Tawfick and his team created used water and a little electricity. It is believed that developments in soft robotics could lead to the creation of machines that are cheaper, require less energy, and produce less waste.

These developments may also revolutionize prostheses for disabled individuals and the elderly. Although current prostheses do offer plenty of support to their users, available models are sorely limited in what they can do and how they move. Artificial muscles – and tendons – could make for prostheses that move and function in a more life-like manner.

Learn more about artificial muscles and similar technologies at FutureScienceNews.com.

Sources include:

Tagged Under: artificial muscle, breakthroughs, carbon fiber, cool science, future science, future tech, inventions, prosthesis, robotics, science and technology, silicone, soft robots